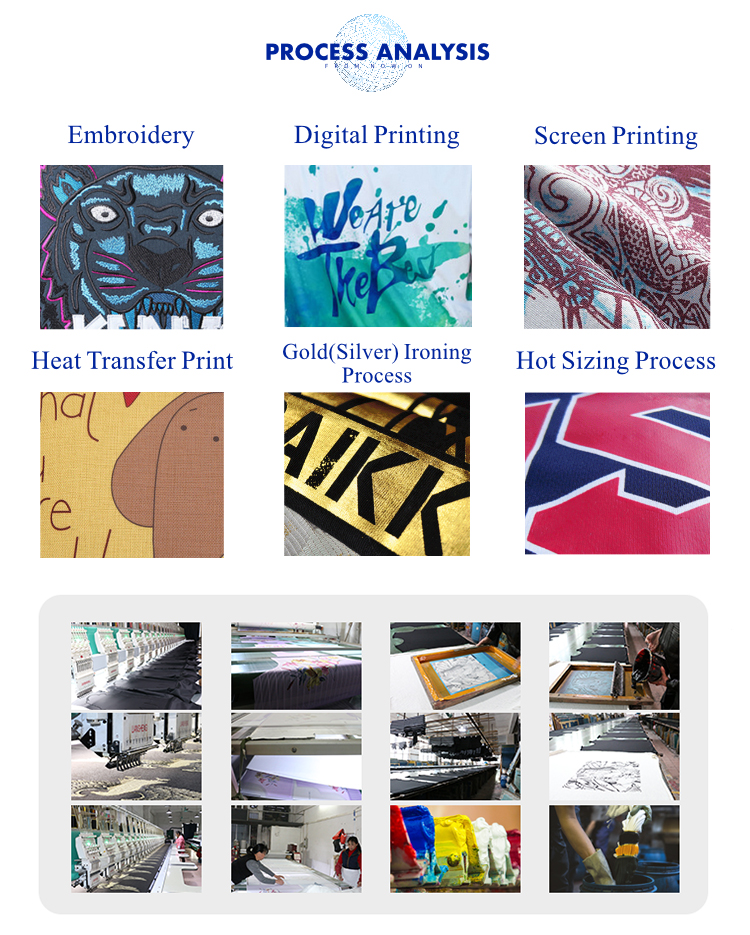

The pattern printing and dyeing methods sweatpants, that is, the printing process, are mainly divided into three types:

1. Screen printing: Because of the low printing cost, screen printing is printed and dyed in the form of plate making, which incurs plate making costs, and is suitable for mass production. Because the screen printing adopts the over-color printing method, it is impossible to achieve the transition of all colors between the two colors according to the picture, and it is difficult to reflect the color transition according to the picture itself. If you want to achieve high-precision, high-complexity printing patterns, screen printing is obviously not suitable.

2. Thermal transfer printing process: Thermal transfer printing is a new type of process that uses thermal transfer equipment to print patterns and images on thermal transfer paper on fabrics through heating transfer.

There are two printing methods for thermal transfer, one is sublimation transfer and the other is thermoset transfer. Dye sublimation is mainly for chemical fiber materials. Thermal transfer undoubtedly achieves the effect of graphic printing with transitional colors and rich layers. However, because the thermal transfer uses intermediate carrier transfer paper, the thermosetting pattern forms a surface on the surface of the attachment after transfer. Layered jelly, with poor hand feeling and airtight.

3. Digital direct-injection printing process: suitable for small batch printing, and can achieve better hand feeling.

Digital direct-injection technology does not require plate making, and directly prints the pattern in the computer on the cotton fabric to achieve a WYSIWYG printing effect. The operation is simple and completely breaks through the traditional screen printing’s color limitation. Digital printing can print 16.7 million colors on the chromatogram with rich colors. The use of high-quality water-based environmentally friendly dyes can ensure that the pigment molecules are completely fused with the cotton fiber under high temperature and high pressure, and achieve the printing effect that the printing pattern can not be seen. It is the most cutting-edge personalized printing solution in China.